Our process of creating a Venetian floor starts with a personalised consultation. After understanding the visions and analysing the needs of each customer, we carry out an on-site visit to gather all the information we need to draw up a tailor-made quote.

The Venetian terrazzo is made entirely by hand thanks to skilful workmanship. Everything necessary is prepared at the work site in order to ensure high quality installation and to create a durable surface.

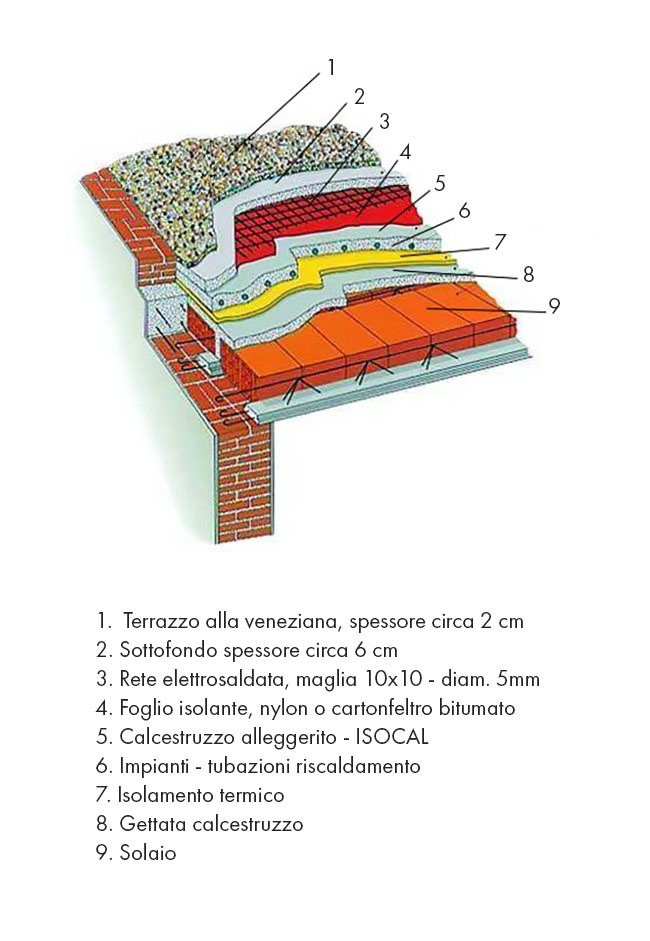

A subfloor is prepared, into which an electrowelded mesh is inserted; a layer consisting of 2-3 cm of small-sized granules mixed with cement is then formed and the ‘seeding’ of marble granules or chippings and earthenware is carried out. It is then beaten to stabilise and level the granules and left to cure for several days, followed by sanding, grouting and polishing.

The Venetian terrazzo is also suitable for the installation of underfloor heating: it facilitates the radiation of heat, ensuring uniform temperature inside the room.

The Venetian floor, also called Venetian terrazzo, is the result of combining elegance and simplicity. It is achieved by completing several steps, including the manual sowing of marble fragments on fresh mortar. These natural stone fragments are joined together with strongly binding cements, resulting in single-coloured or even multi-coloured surfaces that are always unique and different, as it is impossible to reproduce the same seeding or texture.

In addition to materials such as marble, this floor can also be made with mother-of-pearl, precious stones and glass, and enhanced by the addition of frames and mosaics to become a special surface unlike any other. The Venetian terrazzo started out as an elegant classic-style floor, and thanks to customisation it can also become a modern minimalist style floor.

The Venetian terrazzo is a highly valuable surface that is at the same time easy to clean and maintain, in particular due to the absence of joints. The latter creates an effect of continuity on the surface, which ensures a remarkable aesthetic impact and a feeling of considerable depth.

This floor can be customised according to preference, both in terms of materials and colours. A compound of marble granules and pebbles, river stones, gemstones, mother-of-pearl and glass is created. Everything is bound together with binders such as cement or cement and lime and customised according to the client’s requirements.

The materials we use to create Venetian floors are carefully selected to ensure the quality and beauty of the work in full respect of the tradition handed down by the terrazzo masters.

Venetian floors are suitable for a wide range of contexts. In public places such as arcades, places of worship, hotels, restaurants and museums, they add a touch of charm and practicality. In private contexts, such as historic residences and villas, they transform spaces into works of art. Their versatility makes them ideal for any environment where elegance meets durability.

Contact us for more information and a customised quote. We will be happy to assist you in the process of transforming your space with a Venetian floor.

Through specific recovery and restoration work, we deal with the renovation of antique Venetian floors in any context.

Through maintenance and conservative restoration, we are able to contribute to the preservation of the historical heritage represented by Venetian floors.

We create high-quality Venetian floors with great craftsmanship, carefully considering the demands and needs of the customer.

Fill in the form with your best data; our staff will contact you as soon as possible to provide you with all the information you need.

Via Cassiani, 181/b

41122 – Modena (Italia)

Tel. +39 059 450001

Mail. info@franchinipavimenti.com

© 2023 Franchini Pavimenti Srl – VAT 03867810362 – All rights reserved | Site developed by Seo Siti Marketing